© Copyright 2024 EGS Machining - All Rights Reserved

Introduction

When it comes to choosing the right CNC machine shop, there are several factors to consider. First and foremost, assess the range of design services offered by the shop. A reputable machine shop should be able to provide comprehensive design solutions tailored to meet your specific needs. Additionally, it is crucial to find a shop with experienced and skilled machinists who can deliver high-quality work. Look for certifications or qualifications that demonstrate their expertise in the field. Lastly, check if the shop has milling and lathe machining capabilities as these are essential for various manufacturing processes. By considering these factors, you can ensure that you choose a CNC machine shop that meets your requirements and delivers exceptional results.

Design Services and Machinist Expertise

When choosing a CNC machine shop, it is essential to consider the design services they offer and the expertise of their machinists. Look for a shop that can provide comprehensive design solutions to meet your specific needs. This means they should have the capability to handle various design projects, from simple to complex. Whether you require prototyping, reverse engineering, or custom part design, a shop with comprehensive design solutions can cater to your requirements effectively.

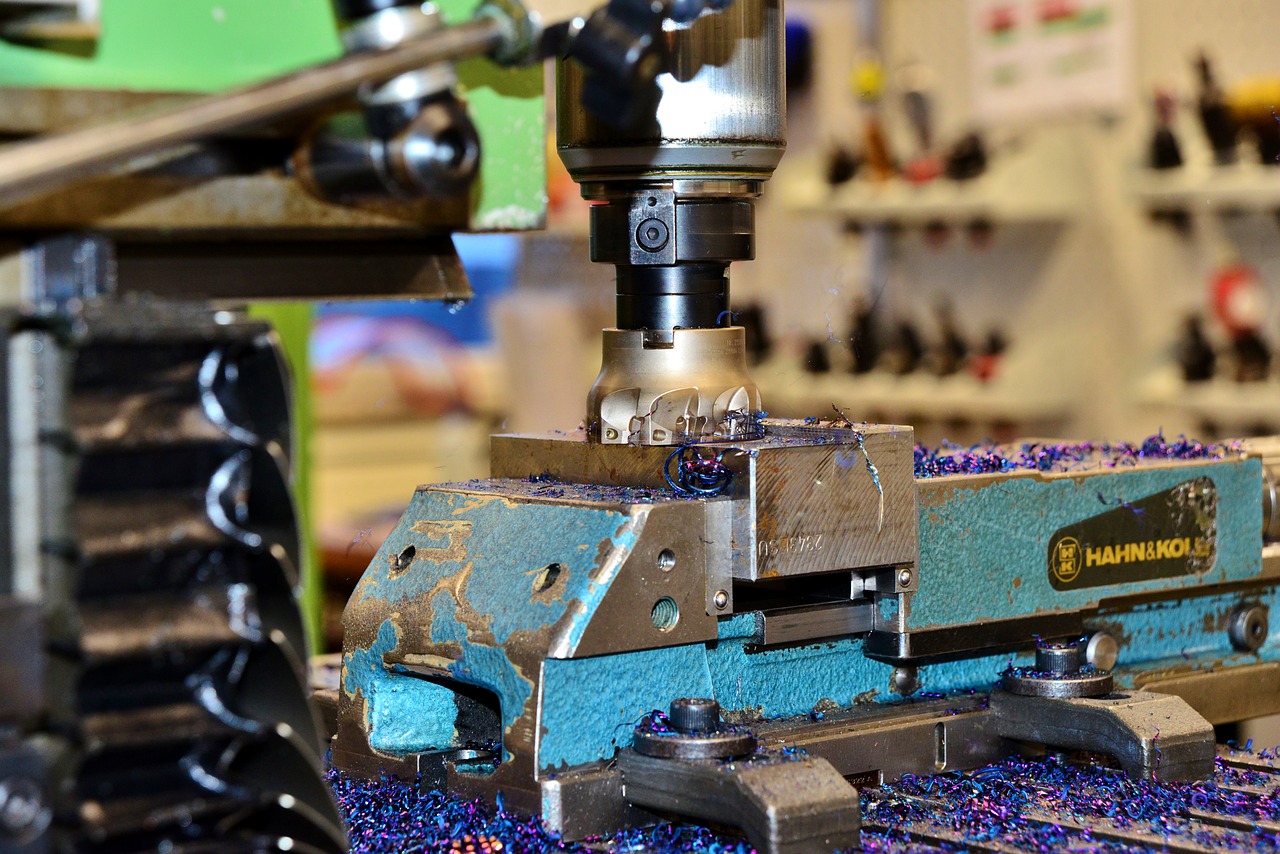

Equally important is finding a shop with experienced and skilled machinists. These are the individuals who will be operating the CNC machines and turning your designs into reality. Skilled machinists possess in-depth knowledge of machining techniques, materials, and tooling. They understand how to optimize the manufacturing process for efficiency and precision.

To ensure that you choose a shop with skilled machinists, check for certifications or qualifications of their staff. Certifications such as CNC programming or machining certifications indicate that the machinists have undergone specialized training and have demonstrated their expertise in the field. Additionally, look for any industry awards or recognition that highlight the shop's commitment to excellence in machining.

By selecting a CNC machine shop with comprehensive design solutions and experienced machinists, you can have confidence in their ability to deliver high-quality work that meets your specifications.

Milling and Lathe Machining Capabilities

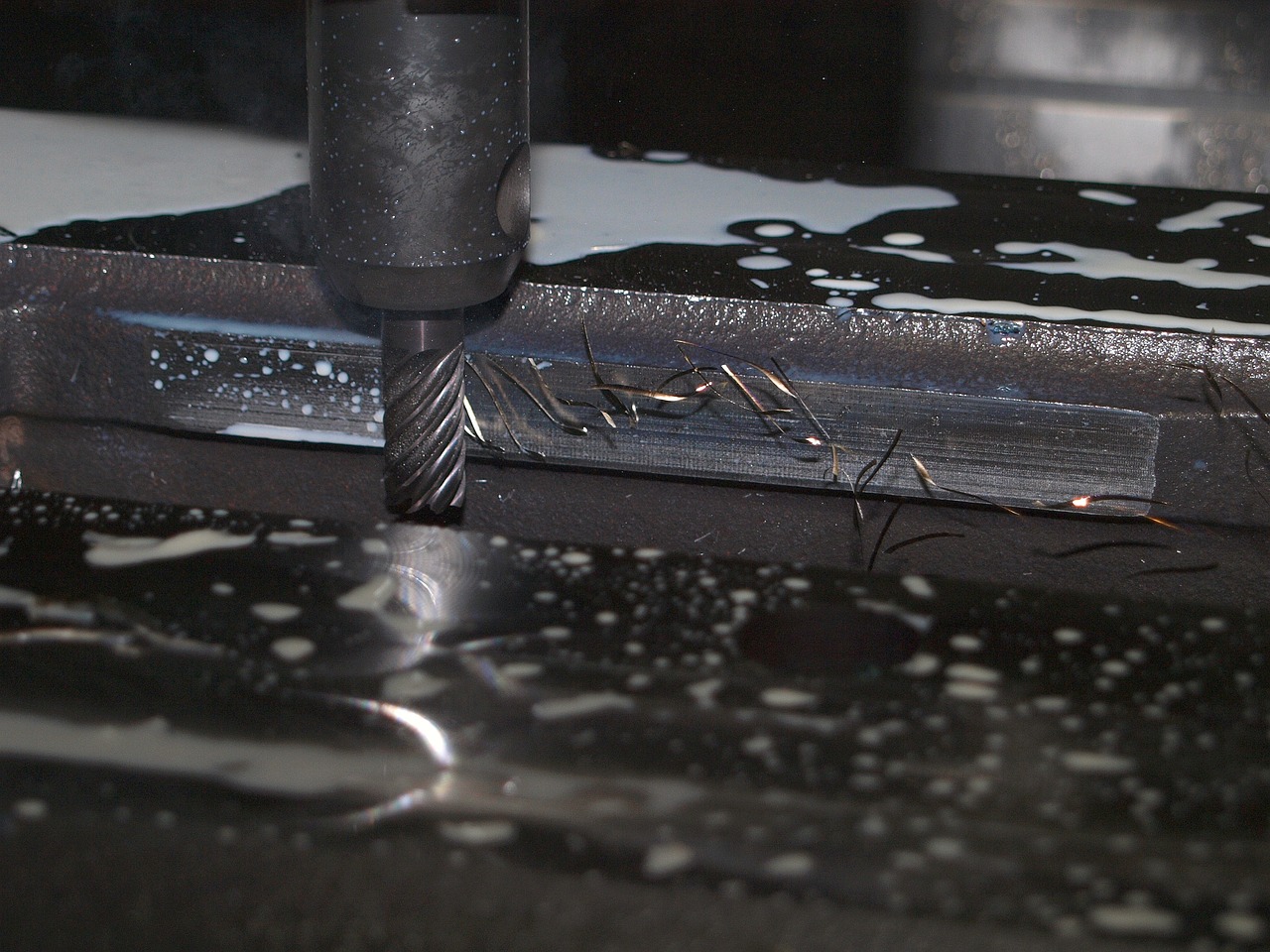

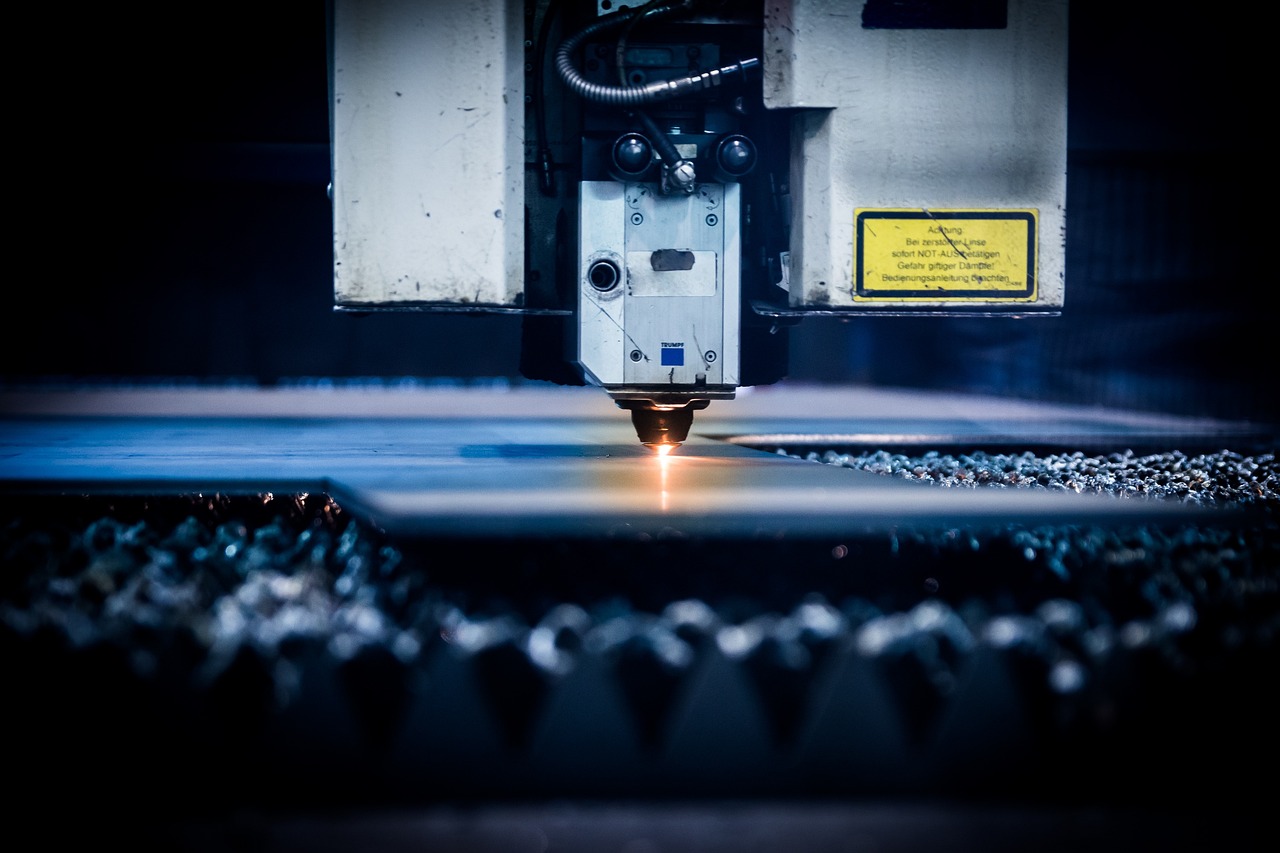

Milling and lathe machining capabilities are crucial factors to consider when choosing a CNC machine shop. These capabilities play a vital role in various manufacturing processes, making them essential for producing high-quality parts and components.

Firstly, check if the shop has milling and lathe machining capabilities. These machines allow for precise shaping, cutting, drilling, and turning of materials. Whether you need intricate designs or complex geometries, having access to milling and lathe machines ensures that your requirements can be met efficiently.

In addition to having these capabilities, it is important to ensure that the shop has advanced milling and lathe machines. Technology in the machining industry is constantly evolving, with new advancements improving accuracy, speed, and efficiency. By choosing a shop with advanced equipment, you can benefit from the latest technological innovations.

Regular equipment updates are also crucial for a CNC machine shop to keep up with industry standards. This demonstrates their commitment to providing high-quality results using state-of-the-art machinery. When evaluating potential shops, inquire about their equipment maintenance practices and how frequently they update their machines.

By selecting a CNC machine shop with milling and lathe machining capabilities as well as advanced equipment and technology, you can have confidence in their ability to deliver precise and efficient manufacturing processes that meet your specifications.

Equipment and Part Repairs

When choosing a CNC machine shop, it is important to consider the availability of equipment and part repairs. Timely repairs can greatly impact the efficiency and reliability of the shop, ensuring that your projects are completed on schedule without unnecessary delays.

Consider the shop's approach to equipment maintenance and repair. A reputable shop should have a dedicated repair team that is skilled in diagnosing and fixing issues with CNC machines. This team should be equipped with the necessary tools and expertise to handle various types of repairs efficiently.

Prompt and reliable repair services are essential for minimizing downtime in production. When a machine breaks down or requires maintenance, you want assurance that it will be repaired quickly to avoid disruptions to your project timelines. Inquire about the average turnaround time for repairs and whether the shop has a system in place to prioritize urgent repairs.

Additionally, ask about their process for sourcing replacement parts. A well-established machine shop should have access to a wide range of spare parts to ensure quick replacements when needed. This helps maintain continuity in production without extended delays waiting for parts to arrive.

By choosing a CNC machine shop that prioritizes equipment and part repairs, you can have peace of mind knowing that any issues will be addressed promptly by a dedicated repair team. This ensures efficient operations and reliable delivery of your projects within the agreed-upon timelines.

Design and Service Prototypes

When selecting a CNC machine shop, it is beneficial to choose one that offers design and service prototypes. Prototypes play a crucial role in testing and refining your designs before proceeding with full-scale production.

A reliable machine shop should have the capability to create prototypes based on your specifications. These prototypes allow you to physically assess the design, functionality, and performance of your product or component. By testing the prototype, you can identify any potential issues or areas for improvement early on, saving time and resources in the long run.

In addition to offering prototypes, look for a shop that encourages a collaborative approach during the prototype phase. This means they actively seek your input and feedback throughout the process. A collaborative approach fosters effective communication between you and the machinists, ensuring that your vision is accurately translated into the final product.

Furthermore, ensure that the shop provides valuable feedback and suggestions for improvement during the prototype stage. Experienced machinists can offer insights based on their expertise, helping you optimize your design for better functionality or cost-effectiveness. Their input can lead to innovative solutions or enhancements that may not have been initially considered.

By choosing a CNC machine shop that offers design and service prototypes along with a collaborative approach, you can benefit from thorough testing and refinement of your designs before committing to full-scale production. This reduces the risk of costly errors or design flaws while ensuring that your final product meets your expectations.

Overall Machining Services

When choosing a CNC machine shop, it is crucial to evaluate the overall machining services they provide and ensure they align with your specific requirements. This assessment allows you to determine if the shop has the capabilities and expertise to meet your manufacturing needs effectively.

Start by reviewing the range of machining services offered by the shop. Consider whether they can handle the size, complexity, and volume of your projects. Some common machining services include milling, turning, drilling, grinding, and precision cutting. Ensure that the shop has experience in these areas and can deliver high-quality results.

Additionally, check if the shop offers any additional services such as assembly or finishing. Having all these services under one roof can be highly convenient and time-saving. It eliminates the need for coordinating with multiple vendors and ensures seamless integration of different manufacturing processes.

Furthermore, consider any specialized requirements you may have. For example, if you work with specific materials such as exotic alloys or plastics, verify that the shop has experience working with those materials. Similarly, if you require tight tolerances or complex geometries, ensure that their equipment and machinists are capable of meeting those specifications.

By evaluating the overall machining services provided by a CNC machine shop and ensuring they align with your specific requirements, you can choose a partner who can effectively handle your projects from start to finish. This ensures a streamlined manufacturing process and consistent quality throughout your production runs.

Conclusion

In conclusion, choosing the right CNC machine shop requires careful consideration of several factors. Assess the range of design services offered by the shop to ensure they can meet your specific needs. Look for a shop with experienced and skilled machinists who can deliver high-quality work. Evaluate the overall machining services provided and ensure they align with your requirements. By taking these steps, you can select a CNC machine shop that will provide exceptional results, efficient manufacturing processes, and meet your expectations throughout your project.