© Copyright 2024 EGS Machining - All Rights Reserved

The Importance of CNC Programming Services

CNC programming services play a crucial role in the manufacturing industry, benefiting professionals, CNC operators, and business owners alike. By utilizing efficient CNC programming techniques, companies can ensure accurate and precise machining operations. This precision leads to improved productivity, reduced costs, and high-quality output. Choosing the right CNC programming service provider is essential to harness these benefits fully. With their expertise and knowledge, these providers can optimize programs for specific machining operations, resulting in increased efficiency and minimized errors. Ultimately, partnering with a reliable CNC programming service provider can significantly enhance manufacturing processes and contribute to overall business success.

Factors to Consider When Selecting a CNC Programming Service Provider

When choosing a CNC programming service provider, several factors need to be taken into consideration. Two critical aspects to evaluate are the provider's experience and expertise, as well as their capabilities and resources.

Experience and Expertise

It is essential to assess the provider's experience in CNC programming. Look for a company that has a proven track record in this field, with years of experience handling various projects. This demonstrates their ability to handle different challenges and adapt to evolving industry requirements.

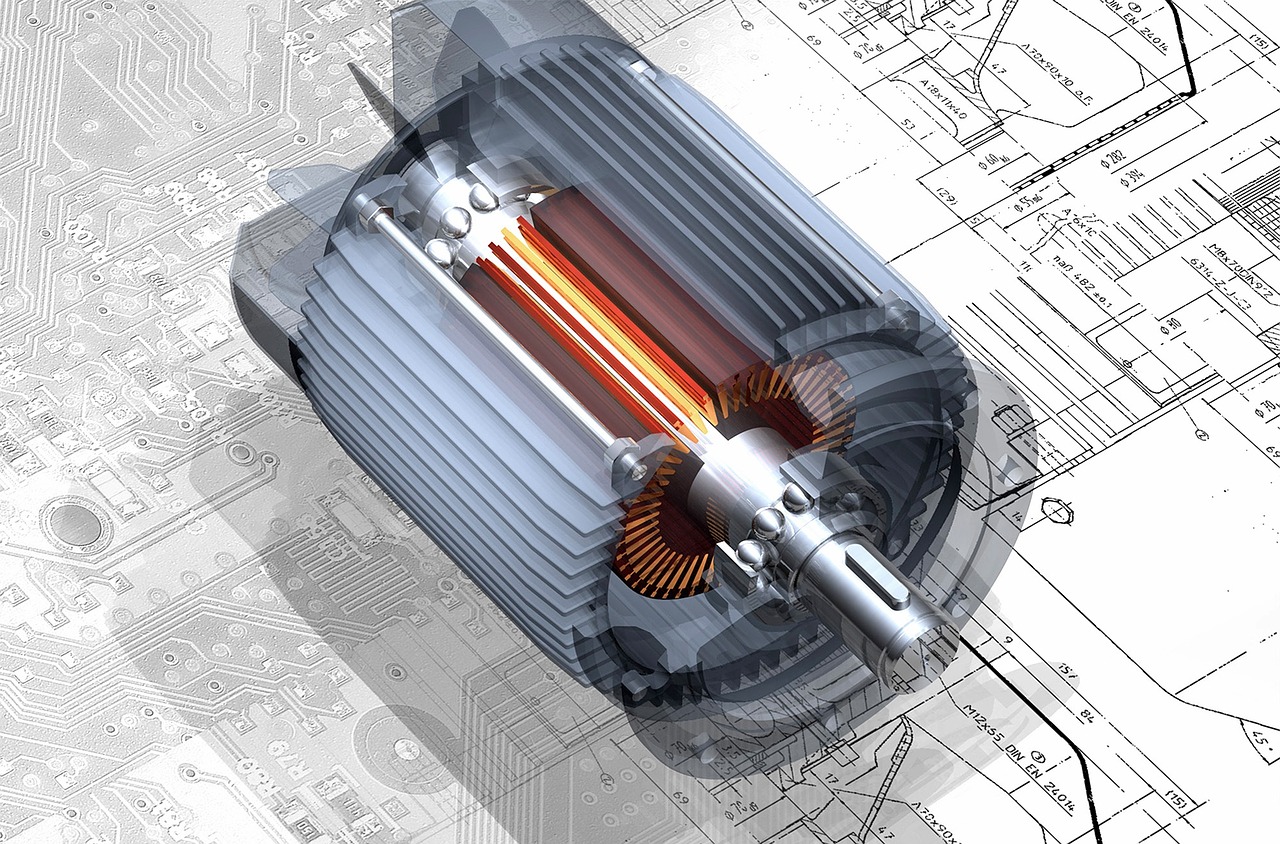

Additionally, consider the provider's expertise in handling different types of CNC machines and software. Each machine may have its unique programming requirements, so it is crucial that the provider has the necessary knowledge and skills to work with your specific equipment. They should be proficient in optimizing programs for different machining operations, ensuring maximum efficiency and accuracy.

Capabilities and Resources

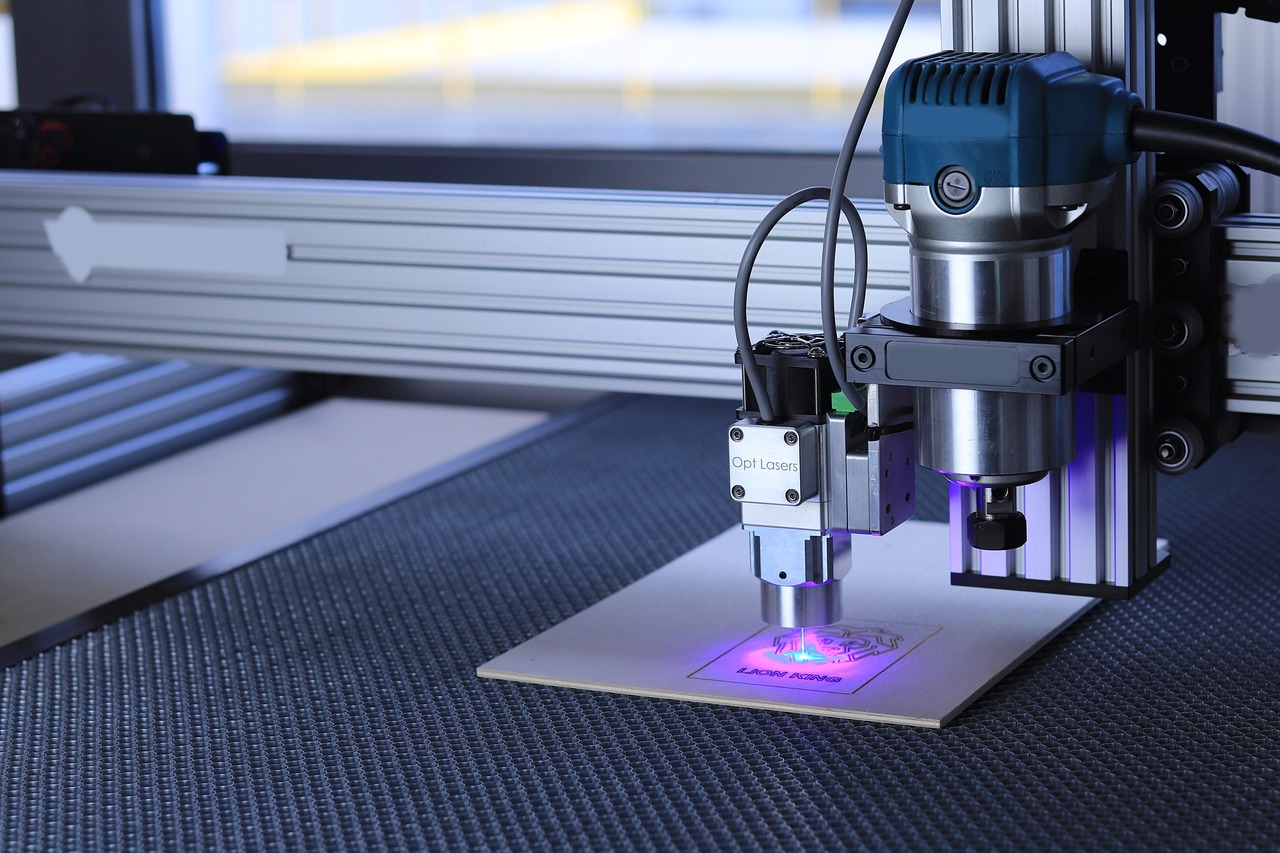

Evaluate the range of programming capabilities offered by the service provider. A reputable company should be able to handle complex programming tasks efficiently. They should have expertise in using CAD/CAM software and various programming languages, enabling them to create precise instructions for your CNC machines.

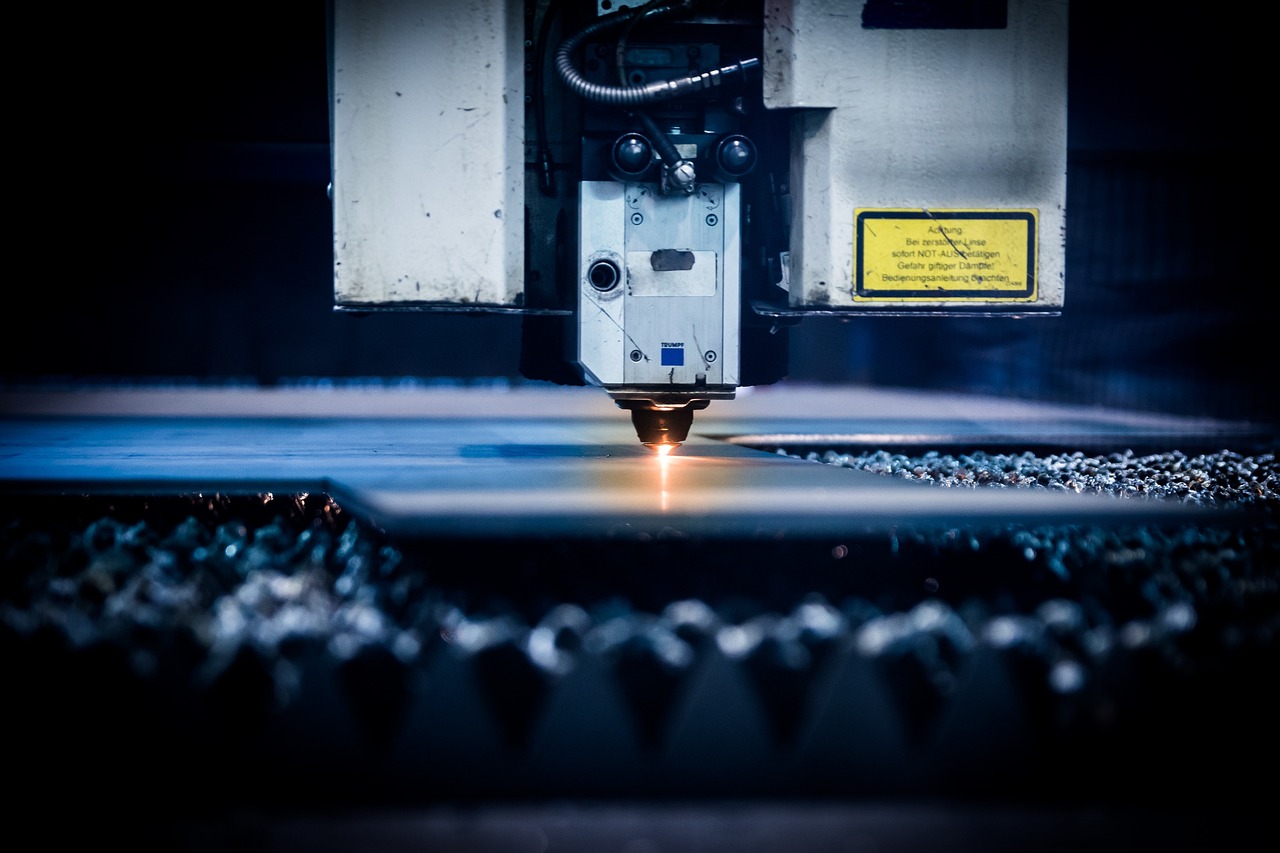

Furthermore, consider their access to advanced tools, software, and equipment. The provider should stay up-to-date with technological advancements in the industry and have access to state-of-the-art CNC machines. This ensures they can meet your manufacturing needs effectively while adapting to changing industry standards.

By carefully evaluating a CNC programming service provider's experience, expertise, capabilities, and resources, you can make an informed decision that aligns with your business requirements.

Experience and Expertise

When selecting a CNC programming service provider, it is crucial to assess their experience and expertise in the field. This section will delve into two key aspects: the provider's experience in CNC programming and their expertise in working with CNC machines and software.

Experience in CNC Programming

Evaluate the provider's years of experience in CNC programming. A company with extensive experience is likely to have encountered various challenges and developed effective solutions over time. Consider their track record of successful projects, as this indicates their ability to deliver high-quality results consistently. An experienced provider can navigate complex programming requirements with ease, ensuring optimal performance for your machining operations.

Expertise in CNC Machines and Software

Assess the provider's knowledge and proficiency when it comes to working with different types of CNC machines and software. Each machine may have unique specifications, so it is essential that the provider understands how to optimize programs for specific machining operations. Look for evidence of their expertise, such as certifications or specialized training, which demonstrate their commitment to staying updated with industry advancements.

Additionally, consider their familiarity with various CAD/CAM software systems commonly used in CNC programming. Proficiency in these tools allows them to create precise instructions for your machines, maximizing efficiency and accuracy.

By carefully evaluating a CNC programming service provider's experience and expertise, you can ensure that they possess the necessary skills and knowledge to meet your specific requirements effectively.

Capabilities and Resources

When choosing a CNC programming service provider, it is essential to evaluate their capabilities and resources. This section will focus on two key aspects: the provider's range of programming capabilities and their access to advanced tools and equipment.

Range of Programming Capabilities

Evaluate the provider's ability to handle complex programming tasks. A reputable CNC programming service provider should have a diverse skill set that enables them to tackle various challenges effectively. Consider their expertise in CAD/CAM software and different programming languages commonly used in CNC programming. This proficiency ensures that they can create precise instructions for your machines, optimizing performance and accuracy.

Additionally, assess their experience with different types of machining operations. Look for evidence of successful projects involving similar processes or industries as yours. This demonstrates their ability to adapt their programming capabilities to meet specific requirements.

Access to Advanced Tools and Equipment

Assess the provider's access to state-of-the-art CNC machines and equipment. The availability of advanced tools allows them to deliver high-quality results efficiently. Consider whether they invest in upgrading their equipment regularly, as this indicates their commitment to staying at the forefront of technological advancements.

Furthermore, evaluate their ability to adapt to evolving technologies and industry standards. The manufacturing industry is constantly evolving, with new techniques and technologies emerging regularly. A reliable CNC programming service provider should demonstrate a willingness to embrace these changes, ensuring that they can meet your future needs effectively.

By considering a CNC programming service provider's range of capabilities and resources, you can ensure that they have the necessary tools and expertise to handle your unique requirements while keeping up with industry advancements.

Reputation and Customer Reviews

When selecting a CNC programming service provider, it is crucial to assess their reputation and consider customer reviews. This section will explore two key aspects: assessing reputation and reading customer reviews and testimonials.

Assessing Reputation

Research the provider's reputation in the industry. Look for information about their background, experience, and any notable achievements. Consider their track record of customer satisfaction and reliability. A reputable CNC programming service provider should have a positive reputation built on delivering high-quality services consistently.

Additionally, seek out recommendations from trusted sources within the manufacturing industry. Networking with peers or seeking advice from industry associations can provide valuable insights into a provider's reputation.

Customer Reviews and Testimonials

Reading customer reviews and testimonials can offer valuable insights into the performance of a CNC programming service provider. Look for platforms where customers share their experiences working with the provider. Pay attention to feedback regarding their communication, responsiveness, and overall service quality.

Customer reviews can provide an unbiased perspective on the provider's strengths and weaknesses. Positive reviews highlighting successful projects, timely delivery, and excellent customer support are indicators of a reliable service provider.

However, it is essential to approach online reviews with discernment, considering both positive and negative feedback. Take note of any recurring themes or concerns raised by multiple customers.

By assessing a CNC programming service provider's reputation and reading customer reviews, you can gain valuable insights into their performance, reliability, and overall satisfaction levels among previous clients. This information will help you make an informed decision when choosing the best provider for your needs.

Making an Informed Decision

Selecting the right CNC programming service provider is crucial for achieving optimal manufacturing operations. By considering various factors such as experience, expertise, capabilities, resources, reputation, and customer reviews, you can make an informed decision that aligns with your business needs.

Choosing a reputable provider with extensive experience in CNC programming ensures that they have the knowledge and skills to handle your specific requirements. Assessing their capabilities and access to advanced tools and equipment guarantees that they can deliver high-quality results efficiently.

Additionally, considering their reputation in the industry and reading customer reviews provides valuable insights into their performance and reliability. Making an informed decision based on these factors can lead to improved efficiency, cost savings, and high-quality output for your manufacturing processes.

By carefully evaluating all these aspects, you can confidently select a CNC programming service provider that will contribute to the success of your business.